According to HSE, around 473,000 workers suffer from work-related injuries and approximately 6.6 million working days are lost. These numbers signify the importance of proper manual handling. This blog will shed light on one of the core components of safe manual handling: TILE. What does TILE stand for? Why is it important? You will find the answers to all the fundamental questions. Stay tuned!

Table of Contents

What is Manual Handling?

The process of moving, lifting, carrying, and shifting objects or loads from one place to another is called manual handling. In many work environments, manual handling is a common task. There is a variety of manual handling tasks. For example, lifting, pushing, carrying, loading, unloading, and more.

What Injuries can be caused by Manual Handling?

While pulling, pushing or lifting heavy loads, many accidents and injuries can occur. Some of these injuries can be short-term, while others can have a long-term impact on the body. Here is a list of some common short and long-term injuries.

Short-Term Injuries

Long-Term Injuries

What does TILE stand for in Manual Handling?

The acronym TILE stands for Task, Individual, Load and Environment. This acronym demonstrates the four main factors that need assessment before starting a manual handling job. The TILE assessment must be conducted before the work starts, as it is a crucial part of the risk assessment procedures.

The TILE assessment plays a significant role in identifying, eliminating and reducing any risk or hazard that can impact the workers. Also, it helps in developing a safe and proper plan for risk-free manual handling.

Task

T the first letter of TILE stands for Task. Task refers to the nature of the manual handling task that needs to be done. It includes the factors associated with the task that may pose health and safety risks. So, when you are assessing manual handling tasks, there are some questions you need to ask.

If you find most of the answers yes, that means this task poses a health risk. You need to find an alternative or take protective measures.

Individual

The second letter, ‘I’ is for individuals. In this stage, the focus of the assessment is the individual who will be doing the task. Each individual has different levels of strength, ability, and capability. Not everyone is trained or built to do the same. Therefore, the risk level for each individual also varies. This is why it is important to evaluate the risk factors for each worker.

In order to do that, you have to find answers to the questions below.

It is important to answer these questions for each individual doing the task. If there is any change in the task or the person, then it’s important to reassess.

Load

Next comes the Load, which is a very important aspect of manual handling. The weight, size, shape, and other related factors can have a significant impact on the manual handling task. The level of risk associated with the task is related to the nature and type of the load. For example, some loads can carry hazardous substances. Therefore, there are serious threats of spoilage, exposure or contamination. Thus, it is vital to assess the load that will be carried or moved around.

To evaluate the load, you should go through this list of questions.

According to the answers to the questions, you must take appropriate measures to make sure the load is safe. If the load is too heavy for people to carry, use lifting equipment or tools.

Environment

The last letter or TILE is ‘E’, which stands for Environment. Here, environment means the area where the task will take place. Environmental elements such as wind, rain, and temperature can have a great impact on the task and the task location. That is why these elements also require consideration while assessing the risks.

The question that needs answering for this assessment are –

These questions will help you develop a proper plan for the task and ensure all safety issues are checked.

What is TILEO?

When there is an ‘O’ added after TILE, it means other factors are also included here. These other factors refer to the elements or factors that are not included in the main four elements of TILE. These factors are as follows –

Why is TILE Important for Manual Handling?

Manual handling can be the reason for serious injuries and accidents. There are many hidden risks we might not see. However, a TILE assessment allows you to find the hazards and health risks. Thus, employers and organisations can plan a detailed risk management plan and prevent injuries caused by manual handling in the workplace.

Along with that, a TILE assessment plays a significant role in educating the employees. It assists in ensuring that the employees are well aware of the proper manual handling methods. This will not only protect them but also enable them to identify and report any potential risks.

TILE assessment helps employers develop a safe workplace, which results in fewer lost hours and lost labour. In addition, conducting this assessment will demonstrate the employer’s concern about the employees. This encourages the employees to be more loyal to their employers. And for any organisation, this can be a great shield against financial losses.

Suppose a worker faces any kind of injury due to the lack of preventive measures taken by the employer. In these cases, the employee can sue the employer or the organisation. This may result in serious penalties and also impact the reputation. However, a TILE will safeguard the employees’ health and protect the organisation from legal issues.

10 Effective Safe Manual Handling Tips

There are many strategies used to ensure safe manual handling. Here is a list of 10 such strategies that will help in reducing manual handling risks. Check them out!

1. Conduct Risk Assessment

Prevention is better than cure, and to prevent manual handling injuries, conducting risk assessment is a must. It will allow you to identify the weak links and take necessary precautions to avoid and reduce injuries. When the nature of tasks changes often, it is important to review the assessment.

2. Plan the Lift or Handling Activity

Assess the task and develop a plan before lifting heavy objects. What is the weight? How to lift it? Can you use lifting aids? How many people are required for the task? Find answers to these questions and then plan the lift. Also, make sure the pathway the workers will use is clear and does not pose any slipping or tripping hazards.

3. Wear the Right Gear

The workers must wear proper clothing and protective gear. In manual handling tasks, there is a great risk of tripping. So, the workers require proper footwear for the task. In addition, there are many tasks that include hazardous substances. In such cases, the workers should follow the strict rule of wearing PPE.

Also, keep in mind that baggy clothing can hinder movement and get caught in corners. That is why workers should wear fitted clothes while they are occupied in manual handling tasks.

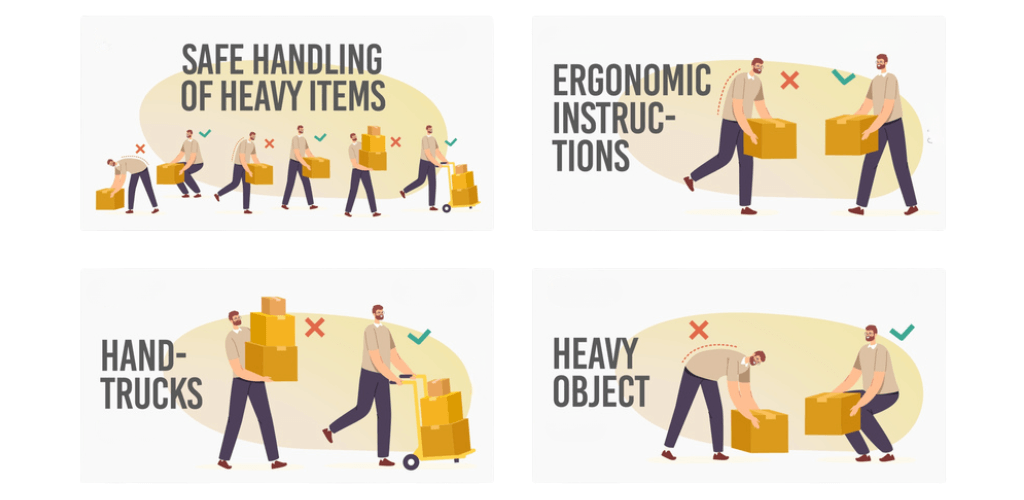

4. Use Lifting Aid

Employees carrying heavy objects or loads are at risk of overexertion, muscle strains, and musculoskeletal injuries. On top of that, there is a serious risk of the load slipping from their hands. Using a lifting aid prevents such injuries and accidents. Thus, when there is an opportunity to use a mechanical lift, make sure to use it.

5. Provide Proper Training

Training can help the workers understand the significance of TILE and enable them to understand the safety precautions better. Through the training, they can learn the proper way to lift, push, and pull loads. It will also help them learn how to use protective gear and lifting machines. As a result, the training will reduce the chances of manual handling injuries.

6. Push Instead of Pulling

When there is an option for both pulling and pushing, the better choice is pushing. Because while pulling, you can not see where you are going. In addition, pulling can put more pressure on your muscles.

On the other hand, when you push objects, you can navigate better, and pushing has a lesser impact on your muscles than pulling. When you push with the lower part of the body while keeping a neutral back posture, the pressure distributes evenly. This prevents the strain from accumulating on a certain part of your body, which can cause injuries.

7. Bend Your Knee

A common mistake while lifting heavy objects is bending the back instead of bending the knee. Our backbone is more fragile and thus prone to greater risk than our knees. That is why the right process is to keep your back straight and bend your knees when you lift something heavy.

8. Keep Your Head up

Like bending the back, another mistake people make is bending their heads and looking down. This prevents them from seeing what’s ahead of them. Also, when you bend your neck, you bend your spine as well. As a result, you can strain your spine and cause spinal injuries. Keeping your head straight will help you see where you are going, and it will protect your spine as well.

9. Hug the Load

The distance between your body and the object is also an important factor. The closer the load is to your body, the less pressure will be on your back. So, it is suggested to hug the load and avoid any kind of twisting or leaning.

10. Report Hazards

When the workers identify any risks or hazards, it is their responsibility to inform the proper authorities. Reporting helps in taking adequate safety measures and prevents any further injuries.

Final Words

Now that you understand what does TILE stand for, it’s time to implement it. If you are the employer, conduct the TILE assessment with utmost seriousness, as you are responsible for the safety and well-being of your employees. However, if you are an employee, make sure to follow the manual handling instructions. You can take our Manual Handling Training Course Also, don’t hesitate to reach out to the authorities if you identify any risks or hazards.

FAQ

The latter T in the acronym TILE stands for Task. It describes the nature of the manual handling task.

The O in TILEO stands for ‘Others’. Here, others refer to the task-related factors that may not fall under the four main factors but can have an impact.

Yes, it is a legal requirement to conduct a TILE assessment in the UK before the workers begin their work.

LITE and TILE are basically the same thing. In LITE the order of the letters are changed. However, the meaning is the same.

Suggested posts

Top 7 SEO Blogs You Should Read for Higher Education Marketing

Smart Tech Maintenance Tips to Enhance Your Learning Experience

How to Strengthen Leadership Skills Through Online Learning